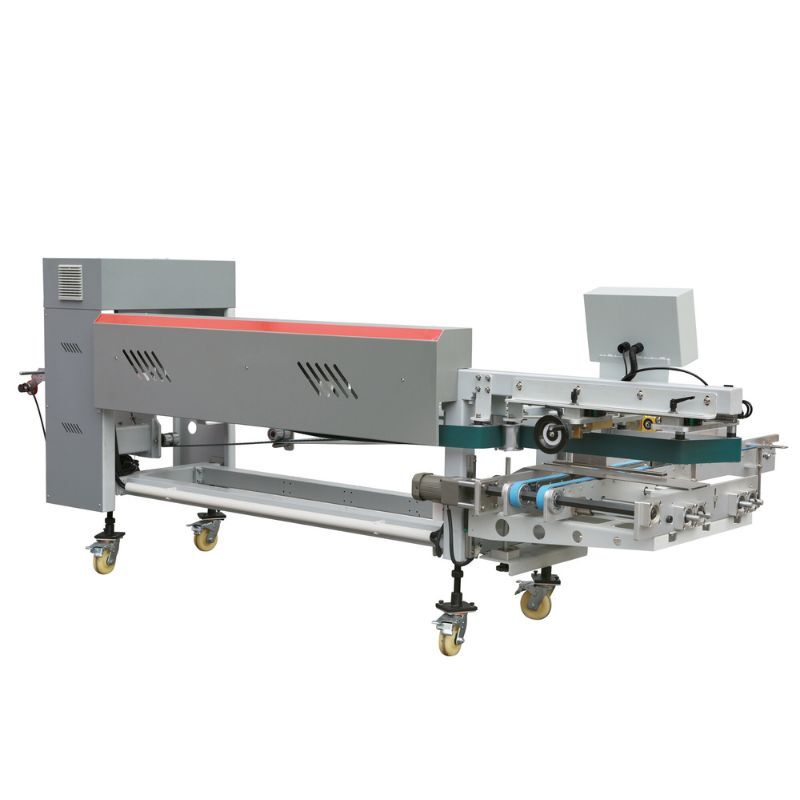

Automatic Folder Gluer Stacker

Price 12000 USD ($)/ Set

Automatic Folder Gluer Stacker Specification

- Lubricating System

- Automatic

- Operating Temperature

- 5C - 45C

- Drive

- Chain drive

- Accuracy

- 1 mm

- Production Capacity

- up to 300 sheets/min

- Cooling System

- Fan cooling

- Features

- Auto stacking, precise folding, easy operation

- Voltage

- 380 V

- Connectivity Options

- Standard interface

- Control System

- PLC Control Panel

- Noise Level

- 78 dB

- Frequency

- 50 Hz

- Machine Type

- Automatic Folder Gluer Stacker

- Frame Type

- Heavy-duty steel frame

- Model No

- AFGS-2200

- Motor Power

- 3.5 kW

- Power Rating

- 7.5 KW

- Product Type

- Automatic Folder Gluer Stacker

- Technology

- High-speed automation

- Power Source

- Electric

- Operating Type

- Automatic

- Power

- 7.5 kW

- Pressure

- Adjustable pneumatic pressure

- Surface Treatment

- Powder coated

- Dimension (L*W*H)

- 8500 mm x 2200 mm x 1600 mm

- Weight (kg)

- 4200

- Color

- Blue & Grey

- Usage & Applications

- Carton box forming, packaging industry

- Conveyor Speed

- Auto-regulated via motor

- Installation Type

- Floor mounted

- Maximum Box Size

- 1100 mm x 780 mm

- Material Thickness

- 28 mm cardboard

- Energy Efficiency

- Optimized consumption design

- Tray Height Adjustment

- Motorized

- Stacking Range

- 15-55 pieces per stack

- Operator Interface

- Touchscreen HMI

- WorkingSpeed

- 60-300 m/min

- Glue Application

- Hot melt/Cold glue compatible

- Minimum Box Size

- 120 mm x 60 mm

- Maintenance Requirement

- Low, due to modular build

- Safety Mechanism

- Emergency stop button, protective covers

Automatic Folder Gluer Stacker Trade Information

- Minimum Order Quantity

- 1 Set

- Main Domestic Market

- All India

About Automatic Folder Gluer Stacker

1. Independent motor driven, can linked with any brand of folder gluer.

2. Can collect many kinds of boxes, such as straight line box, double sides box, crash lock bottom box, four corner box and fine flute corrugated box.

3.Manual/Automatic dual mode, automatic mode can coordinate with folder gluer automatically, no need manual adjustment.

4. Horizontal delivery platform can be electrically adjusted to fit different size boxes.

Versatile Box Forming Capability

The Automatic Folder Gluer Stacker adapts to a range of cardboard sizes and thicknesses, accommodating boxes from very compact to extremely large. Precision controls and motorized adjustments ensure every fold and glue application meets strict quality requirements for diverse packaging needs.

User-Friendly Automation & Operation

A touchscreen HMI interface makes setting up and monitoring jobs simple for operators of all experience levels. Automated speed, pressure, and stacking adjustments streamline workflow. Emergency stop and protective covers provide robust on-site safety, while the PLC control system ensures consistent, accurate results.

Reliable, Efficient Production

With a high-speed output of up to 300 sheets per minute and an energy-efficient 7.5 kW motor, this machine supports large-scale production while minimizing energy usage. Stacks of 15 to 55 pieces simplify downstream operations. The heavy-duty powder-coated steel frame guarantees long-term durability in any industrial setting.

FAQ's of Automatic Folder Gluer Stacker:

Q: How does the conveyor speed adjust on the Automatic Folder Gluer Stacker?

A: The conveyor speed is automatically regulated by the integrated motor system, allowing the machine to maintain optimal output rates between 60 and 300 meters per minute. This ensures smooth material flow according to the set box size and production requirements.Q: What materials and box sizes can this folder gluer stacker handle?

A: It processes cardboard with a thickness of 2 to 8 mm and can handle box sizes ranging from 120 mm x 60 mm up to 1100 mm x 780 mm. This wide range makes it suitable for nearly all common packaging applications in the carton industry.Q: When should the tray height be adjusted and how is it done?

A: Tray height must be adjusted whenever changing to different box sizes or altering stack height, which ranges from 15 to 55 pieces. Adjustment is performed quickly and precisely through the motorized height control, accessible via the touchscreen HMI.Q: Where is this machine ideally installed?

A: Designed for floor mounting, the Automatic Folder Gluer Stacker fits best in industrial production and packaging facilities. Its robust steel frame and dimensions (8500 x 2200 x 1600 mm) require allocation of suitable floor space and electric connections (380 V, 7.5 kW power rating).Q: What is the glue application process and what types of glue are supported?

A: The machine supports both hot melt and cold glue applications. Glue is applied automatically and evenly, ensuring strong, durable bonds according to specific carton requirements. Operators can select the type of adhesive suitable for their production from the HMI interface.Q: How does the operator interface enhance usability and safety?

A: The operator interface is a user-friendly touchscreen HMI, providing simple setup, monitoring, and real-time adjustments. Safety is ensured by an emergency stop button, protective covers, and alert functions, making operation secure and accessible.Q: What are the main benefits of choosing this automatic folder gluer stacker?

A: Benefits include high-speed, consistent operation, flexibility in box sizes and types, energy-efficient performance, low maintenance due to modular design, and an intuitive control system. These features combine to boost productivity, quality, and workplace safety in carton packaging.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Packaging Machine Category

Automatic Honeycomb Paper-Sheet Cutting Wrapping Machine

Price 380 USD ($) / Set

Minimum Order Quantity : 1 Set

Weight (kg) : Approx. 750 kg

Dimension (L*W*H) : 2200 x 1100 x 1700 mm

Power Source : Other, Electric

Control System : Other, Touchscreen PLC

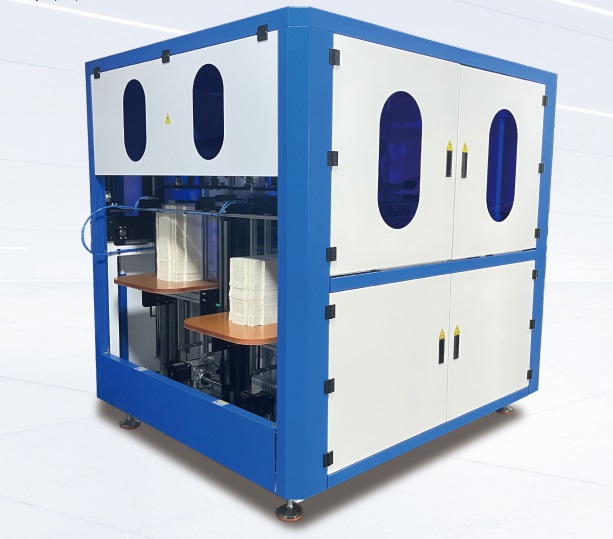

Automatic Honeycomb Paper Sleeve Forming Machine

Price 24000 USD ($) / Set

Minimum Order Quantity : 1 Set

Weight (kg) : 1350 kg

Dimension (L*W*H) : 3200 x 1100 x 1500 mm

Power Source : Other, Electric

Control System : Other, PLCBased Automatic Control

Drug packaging wire machine

Minimum Order Quantity : 1 Set

Weight (kg) : 629 Kilograms (kg)

Dimension (L*W*H) : 350 Centimeter (cm)

Power Source : Electricity

Box Making machine Box Folding Gluing Machine Artpaper Box Forming Machine Top and Bottom Box Mobile box, shirt box

Price 3999.0 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 1200 Kilograms (kg)

Dimension (L*W*H) : 3550* 1550*2000 Millimeter (mm)

Power Source : Pneumatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free