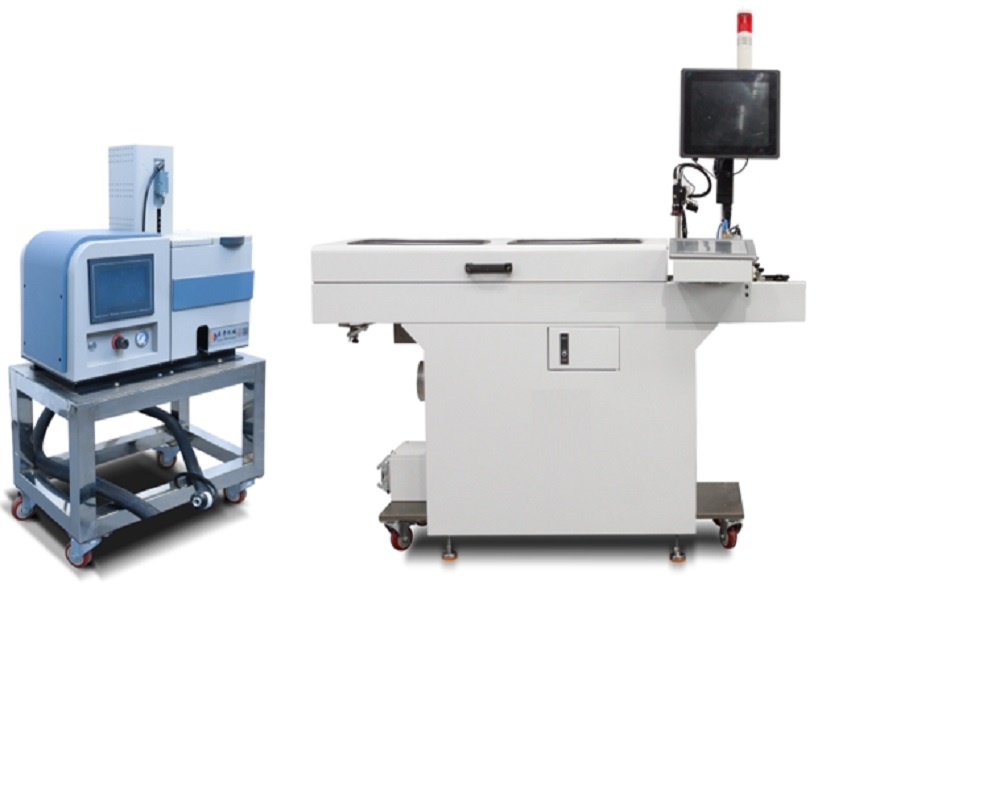

Drug packaging wire machine

Drug packaging wire machine Specification

- Power Rating

- 4.75kw

- Voltage

- 380 Volt (v)

- Product Type

- Other

- Technology

- Other

- Power Source

- Electricity

- Operating Type

- Automatic

- Power

- 4750 Watt (w)

- Surface Treatment

- Other

- Dimension (L*W*H)

- 350 Centimeter (cm)

- Weight (kg)

- 629 Kilograms (kg)

- Warranty

- 1 year

- Production Capacity

Drug packaging wire machine Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- Shenzhen

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 100 Sets Per Month

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- PLYWOOD BOX

- Main Domestic Market

- All India

About Drug packaging wire machine

TS Drug packaging wire :

Automatic High-Performance Packaging

This machine utilizes a fully automatic operating system, reducing manual labor and maximizing packaging efficiency. Its strong 4.75 kW power rating ensures consistent output across demanding production schedules, making it a reliable choice for high-throughput pharmaceutical environments.

Robust Construction for Industrial Use

Manufactured with durability in mind, the packaging wire machine weighs 629 kilograms, providing solidity during operation. The dimensions allow it to accommodate large batches and integrate seamlessly into existing production lines, supporting both scalability and stability.

FAQs of Drug packaging wire machine:

Q: How does the drug packaging wire machine operate automatically?

A: The machine is equipped with an automatic control system that manages the entire packaging process from wire feeding to completion, requiring minimal human intervention for smooth, efficient operation.Q: What is the recommended power source and voltage for this machine?

A: This packaging wire machine is powered by electricity and requires a voltage of 380 volts, with a power rating of 4.75 kW (4750 watts) for optimal performance.Q: When should routine maintenance be performed on the drug packaging wire machine?

A: Routine maintenance should be conducted according to the manufacturers guidelines, usually every few months or after significant production cycles. Regular checks help sustain efficiency and prolong the lifespan of the machine.Q: Where is the drug packaging wire machine manufactured and can it be exported globally?

A: The machine is manufactured in China and is available for distribution and export worldwide through authorized distributors, suppliers, and exporters.Q: What is the step-by-step process for using this packaging machine?

A: First, connect the machine to a suitable electrical outlet (380V). Next, load the packaging wire and initiate the automatic operation via the control panel. The system will handle feeding, packaging, and sealing until completion.Q: How can users benefit from using an automatic drug packaging wire machine?

A: Users benefit from accelerated packaging speed, reduced labor costs, minimized errors, and enhanced consistency in each production batch, making the overall drug packaging process more streamlined and cost-effective.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Packaging Machine Category

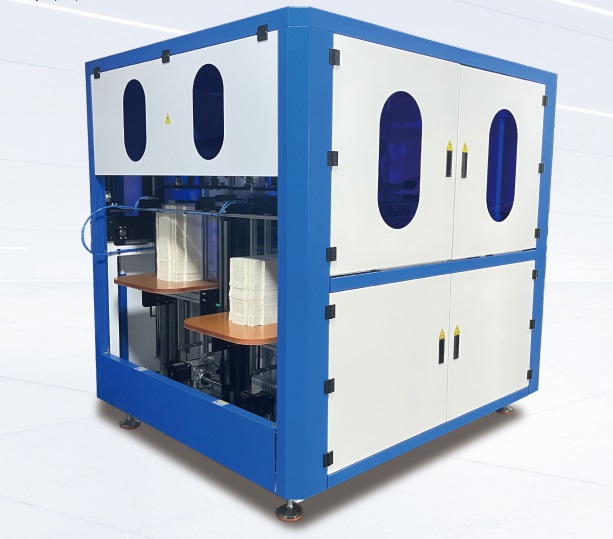

Automatic Honeycomb Paper Sleeve Forming Machine

Price 24000 USD ($) / Set

Minimum Order Quantity : 1 Set

Weight (kg) : 1350 kg

Power Source : Other, Electric

Control System : Other, PLCBased Automatic Control

Dimension (L*W*H) : 3200 x 1100 x 1500 mm

Automatic Honeycomb Paper-Sheet Cutting Wrapping Machine

Price 380 USD ($) / Set

Minimum Order Quantity : 1 Set

Weight (kg) : Approx. 750 kg

Power Source : Other, Electric

Control System : Other, Touchscreen PLC

Dimension (L*W*H) : 2200 x 1100 x 1700 mm

Pur Gluing Machine

Price 3999 USD ($) / Set

Minimum Order Quantity : 1 Set

Weight (kg) : 350 kg

Power Source : Other, Electric

Control System : Other, Digital Touch Screen

Dimension (L*W*H) : 1200 x 750 x 1500 mm

Box Making machine Box Folding Gluing Machine Artpaper Box Forming Machine Top and Bottom Box Mobile box, shirt box

Price 3999.0 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 1200 Kilograms (kg)

Power Source : Pneumatic

Dimension (L*W*H) : 3550* 1550*2000 Millimeter (mm)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free