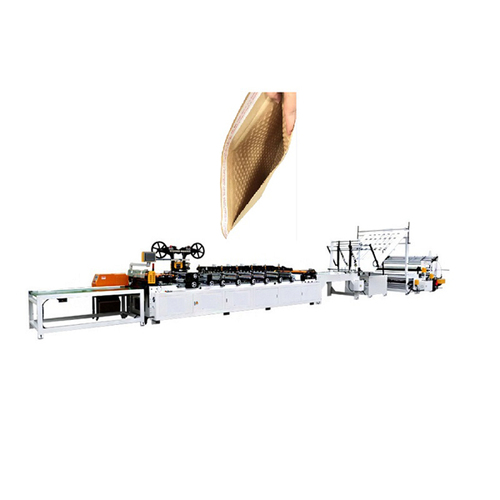

Corrugated Paper Buffer Courier Bag Making Machine

Price 120000 USD ($)/ Set

Corrugated Paper Buffer Courier Bag Making Machine Specification

- Product Type

- Corrugated Paper Buffer Courier Bag Making Machine

- General Use

- Manufacturing of buffer courier bags for safe packaging

- Efficiency

- High efficiency, suitable for continuous production

- Weight (kg)

- Approx. 1800 kg

- Automatic Grade

- Automatic

- Drive Type

- Electric

- Bag Type

- Courier/Buffer Bag

- Computerized

- Yes

- Photoelectric Correction

- Yes

- Film Length Counter

- Yes

- Bag Length

- Adjustable, 100mm 600mm

- Power

- 12 kW

- Voltage

- 220V/380V

- Material

- Corrugated Paper

- Dimension (L*W*H)

- 7800mm x 2300mm x 1800mm

- Feature

- High precision, sturdy construction, efficient sealing and cutting

- Color

- Industrial grey

- Control System

- PLC touch screen

- Noise Level

- Low (<75 dB)

- Safety Features

- Emergency stop; overload protection

- Service Support

- Remote technical assistance

- Conveying System

- Automatic belt transfer

- Max Bag Width

- 600 mm

- Temperature Control

- Digital adjustable

- Production Speed

- Up to 120 bags/min

- Installation

- Onsite setup available

- Sealing Type

- Hot-melt adhesive sealing

- Operator Interface

- User-friendly touch panel

Corrugated Paper Buffer Courier Bag Making Machine Trade Information

- Minimum Order Quantity

- 1 Set

- Payment Terms

- Cash Advance (CA)

- Main Domestic Market

- All India

About Corrugated Paper Buffer Courier Bag Making Machine

1. This machine is special designed for making corrugated paper envelope bag.

2. Bag making method: Loading the two layers of kraft paper on the unwinding rack , forming the corrugated paper from the paper corrugating and lamination machine, applying glue on crosswise bag edge sealing part in the process of moving forward, roller type single folding or double folding, apply red strip, three times of mechanical heat sealing, two times of mechanical cold pressing, roll pressing the easy tear line, cold cutting etc. And then make a standard corrugated paper courier envelopes.

3. This machine uses multi point advanced motion controller technology. The whole machine is equipped with 7 servo system. It is controlled by computer program from film unwinding to cutting. This machine is a high-quality, easy-operational and professional one to make good-looking, durable and environment-friendly bags.

Advanced Automation and Efficiency

This machine automates the entire buffer courier bag production process, from precise cutting to efficient sealing, driven by a computerized PLC touch screen system. With a fast output rate and automatic belt conveying, it is ideal for high-volume packaging needs. The integration of photoelectric correction and adjustable bag length maximizes productivity, ensuring each bag meets strict industry standards.

Precision Sealing and Sturdy Build

Featuring hot-melt adhesive sealing, the machine delivers robust, secure closures on every bag, enhancing package safety during transit. Its sturdy construction and high-precision components guarantee long-term reliability and low maintenance. Digital temperature controls and overload protection further enhance its operational safety and efficiency.

Intuitive User Experience and Support

Operators benefit from an accessible touch panel interface and onsite installation services for rapid deployment. Remote technical assistance ensures ongoing support, while low operational noise and emergency stop functions create a safe and comfortable working environment. This machine brings user convenience and professional-grade automation together.

FAQ's of Corrugated Paper Buffer Courier Bag Making Machine:

Q: How does the Corrugated Paper Buffer Courier Bag Making Machine optimize the production process?

A: The machine automates crucial stages including bag cutting, sealing, length adjustment, and transfer via an automatic belt system. With computerized PLC control and photoelectric correction, it ensures precise operations and consistent high-speed output, optimizing production with minimal manual intervention.Q: What types of bags can be produced with this machine and what materials does it support?

A: It is specifically engineered for making buffer and courier bags using corrugated paper as the primary material; bag widths of up to 600 mm and adjustable lengths between 100 mm and 600 mm are supported, accommodating various packaging requirements.Q: When is onsite setup or remote support provided for this machine?

A: Onsite installation is available when the machine is delivered or commissioned. Remote technical assistance is accessible anytime during the machine's operational life, ensuring technical support and troubleshooting whenever required.Q: Where is this machine best utilized?

A: Ideal for packaging factories, fulfillment centers, and manufacturing lines requiring bulk production of protective courier bags, the machine serves manufacturers, distributors, exporters, and suppliers seeking efficient, reliable packaging solutions.Q: What is the process for bag making and sealing with this machine?

A: Corrugated paper is automatically fed, measured, and cut to the desired length. The bag is then sealed using hot-melt adhesive under precise digital temperature control. Finished bags are transferred via an automatic belt conveyor for collection or further processing.Q: How does the machine enhance operational safety and ease of use?

A: Safety features like emergency stop and overload protection prevent accidents. The user-friendly PLC touch screen interface simplifies adjustments and monitoring, supporting safer, more intuitive operation.Q: What are the main benefits of using this buffer courier bag making machine?

A: Key benefits include high production rates, precise and secure sealing, robust machine construction, low noise levels, and reliable technical support. These features ensure higher efficiency, improved packaging quality, and overall operational convenience for end-users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Courier Paper Bag Machine Category

Honeycomb Paper Cushion Bag Making Machine

Price 99999 USD ($) / Set

Minimum Order Quantity : 1 Set

Drive Type : Other, Servo motor drive

Automatic Grade : Fully Automatic

General Use : Packaging and protective bag production for shipping and logistics

Computerized : Yes

Bubble Paper Envelope Bag Machine For Clothing

Price 120000 USD ($) / Set

Minimum Order Quantity : 1 Set

Drive Type : Electric

Automatic Grade : Automatic

General Use : Manufacturing bubble paper envelope bags used for clothing and related industries

Computerized : Yes

Glassnie Bag Machine

Price 45000 USD ($) / Set

Minimum Order Quantity : 1 Set

Drive Type : Other, Servo motor

Automatic Grade : Automatic

General Use : Manufacturing and sealing of glassine bags

Computerized : Yes

E-Commrce Kraft Paper Bubble Mailing Bag Machine

Price 999999 USD ($) / Set

Minimum Order Quantity : 1 Set

Drive Type : Electric

Automatic Grade : Automatic

General Use : Industrial

Computerized : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free