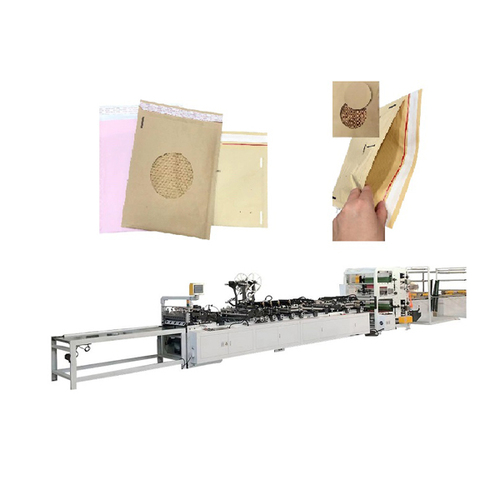

Bubble Paper Envelope Bag Machine For Clothing

Price 120000 USD ($)/ Set

Bubble Paper Envelope Bag Machine For Clothing Specification

- Product Type

- Bubble Paper Envelope Bag Machine for Clothing

- General Use

- Manufacturing bubble paper envelope bags used for clothing and related industries

- Efficiency

- High efficiency, up to 120 bags/min depending on bag size

- Weight (kg)

- 2100 kg

- Automatic Grade

- Automatic

- Drive Type

- Electric

- Bag Type

- Bubble mailer, padded envelope bag

- Computerized

- Yes

- Photoelectric Correction

- Yes

- Film Length Counter

- Integrated digital counter

- Bag Length

- 100-360 mm (adjustable)

- Power

- 8 kW

- Voltage

- 380V/50Hz

- Material

- Kraft paper, bubble film, PE composite materials

- Dimension (L*W*H)

- 7850 x 1600 x 1900 mm

- Feature

- Servo control, PLC touch screen, automatic tracking, high precision, energy-saving

- Color

- Gray & Blue

- Machine Speed

- Up to 120 pieces per minute

- Sealing Method

- Hot melt adhesive/glue sealing

- Operator Needed

- 1-2 persons

- Control System

- PLC with HMI touchscreen

- Installation Support

- Available

- Temperature Control

- Intelligent temperature controller for sealing and cutting

- Max Bag Width

- 500 mm

- Noise Level

- Less than 80 dB

- Air Pressure

- 0.6 MPa (required for operation)

- Applicable Paper Weight

- 60-120 gsm

Bubble Paper Envelope Bag Machine For Clothing Trade Information

- Minimum Order Quantity

- 1 Set

- Payment Terms

- Cash Advance (CA)

- Main Domestic Market

- All India

About Bubble Paper Envelope Bag Machine For Clothing

Affected by the pandemic COV-19, people are more accepting of online shopping, e-commerce business is booming.

But at the same time, we must take good care of the earth on which we live, and meet the double-carbon environmental protection standard as soon as possible.

In this case, express paper bag packaging has come into our sight and has been taken seriously. Paper bags replace plastic bags, while reducing costs, good packaging makes your products look more high-end. E-com mailing bag making machine, Update your equipment, keep up with the trends, and bring you more orders.

None of these bags have any plastic in them at all. They are all sealed by glue, and they are completely recyclable, so they are truly eco-friendly. You may say that if there is so much wood to make paper? ! Is this another form of waste? No ! With today's advanced technology, paper making is nolonger a simple use of wood pulp to make paper.

There are so much recycled paper, straw pulp paper, straw paper and bamboo pulp paper etc. With a technical term description it will be: All fibrous plants with a growth cycle of six months to one year can be used as raw materials for paper making! ! And these papers are all environmentally friendly that can be used to make pure degradable bags. At the same time, you don't need to worry about waterproofing.

Ordinary Kraft paper can be waterproof after being treated, and the paper factory also has waterproof paper, and the price is also acceptable.

Advanced Sealing Technology

Utilizing hot melt adhesive and glue sealing, the machine delivers strong, durable seals ideal for protecting clothing items during shipping. The intelligent temperature controller ensures that every envelope is properly sealed while minimizing waste from errors.

Efficient, High-Speed Production

This machine operates at impressive speeds, manufacturing up to 120 bags per minute. Equipped with servo control and automatic tracking, it maximizes output while requiring minimal manual intervention, making it an excellent choice for modern manufacturing operations.

Smart Control and Precision

With a PLC touch screen and integrated digital film length counter, operators benefit from intuitive controls and accurate performance. Photoelectric correction maintains alignment for consistent quality, further reducing defects in production.

FAQ's of Bubble Paper Envelope Bag Machine For Clothing:

Q: How does the Bubble Paper Envelope Bag Machine optimize efficiency during manufacturing?

A: The machine combines automated high-speed production (up to 120 pieces per minute), computerized PLC control, and servo tracking to streamline envelope bag manufacturing. It adjusts bag length dynamically and maintains optimal sealing and cutting temperatures for consistent performance with minimal operator input.Q: What types of materials are compatible with this machine for producing padded envelope bags?

A: It is engineered to handle kraft paper, bubble film, and PE composite materials, allowing flexibility for various protective packaging requirements. These materials are commonly used in the clothing industry to ensure secure shipment and protection of garments.Q: When should the temperature and air pressure settings be adjusted, and how are they controlled?

A: Adjustments to temperature and air pressure may be necessary when switching bag sizes, material thickness, or during initial setup. The machine features an intelligent temperature controller for precise temperature regulation, while the required operational air pressure is set at 0.6 MPa for optimal sealing and cutting.Q: Where is installation support available for the Bubble Paper Envelope Bag Machine?

A: Installation support is provided, and the machine is suitable for deployment in clothing manufacturers, distributors, exporters, and other related industries looking to automate their packaging lines in China or abroad.Q: What is the process for producing bubble paper envelope bags using this machine?

A: The production involves feeding suitable materials into the machine, selecting desired bag length and width via the HMI touchscreen, and activating automated processes. The system cuts, seals, counts, and photoelectrically corrects each envelope, ensuring high precision throughout.Q: How many operators are needed to run the machine efficiently and what level of expertise is required?

A: Typically, only 1-2 trained personnel are necessary to operate the machine, thanks to its user-friendly PLC touchscreen interface and automated features. Basic training on the control system and material handling is recommended for optimal efficiency and safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Courier Paper Bag Machine Category

Corrugated Paper Buffer Courier Bag Making Machine

Price 120000 USD ($) / Set

Minimum Order Quantity : 1 Set

Automatic Grade : Automatic

Computerized : Yes

General Use : Manufacturing of buffer courier bags for safe packaging

Drive Type : Electric

Honeycomb Paper Cushion Bag Making Machine

Price 99999 USD ($) / Set

Minimum Order Quantity : 1 Set

Automatic Grade : Fully Automatic

Computerized : Yes

General Use : Packaging and protective bag production for shipping and logistics

Drive Type : Other, Servo motor drive

Honeycomb Paper Bag Making Machine

Price 999999 USD ($) / Set

Minimum Order Quantity : 1 Set

Automatic Grade : Semi Automatic

Computerized : No

General Use : Industrial

Drive Type : Electric

Kraft Paper Bottom Gusset Courier Bag Machine

Price 999999 USD ($) / Set

Minimum Order Quantity : 1 Set

Automatic Grade : Semi Automatic

Computerized : No

General Use : Industrial

Drive Type : Electric

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free