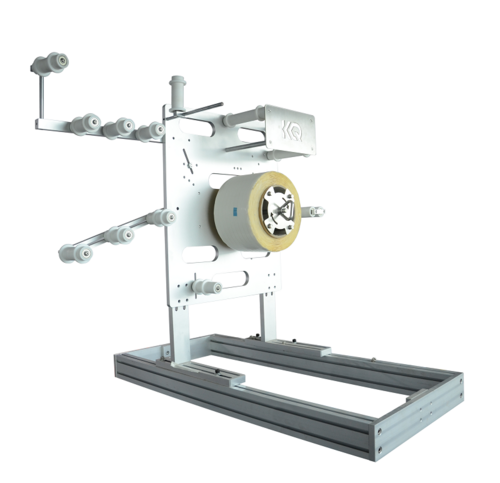

Cold Gluing Systems Machine Hz8-1:9 Multi Channel

Price 9999 USD ($)/ Set

Cold Gluing Systems Machine Hz8-1:9 Multi Channel Specification

- Voltage

- 220V / 50Hz

- Machine Type

- Multi Channel Cold Gluing

- Features

- Multi Channel, Precise Glue Application, Low Maintenance, Touch Screen, Fast Changeover

- Operating Temperature

- 5C - 40C

- Model No

- Hz8-1:9

- Connectivity Options

- Ethernet/USB for Software Update

- Cooling System

- Air Cooled

- Drive

- Electric Motor Driven

- Accuracy

- 0.5 mm

- Production Capacity

- Up to 9000 pcs/h

- Lubricating System

- Automatic Lubrication

- Frequency

- 50 Hz

- Noise Level

- < 70 dB

- Control System

- Microcontroller / PLC Based

- Motor Power

- 90 W (Stepper/Servo Motor)

- Frame Type

- Heavy Duty Steel Frame

- Power Rating

- 180 Watts

- Product Type

- Cold Gluing Systems Machine

- Technology

- Multi Channel Cold Glue Application

- Power Source

- Electric

- Operating Type

- Automatic

- Power

- Approx. 180W

- Pressure

- 0.3 - 0.6 MPa (3-6 Bar)

- Surface Treatment

- Powder Coated

- Dimension (L*W*H)

- 1200 550 850 mm

- Weight (kg)

- 120 kg

- Color

- Industrial Gray / Blue

- Usage & Applications

- Carton Sealing, Packaging, Bookbinding, Printing, Paper Bag Manufacturing

- Drive

- Servo Motor Drive

- Min. Paper Thickness

- 90 gsm

- Installation Support

- Yes

- Glue Type

- Water-based cold glue

- User Interface

- Touch Screen (HMI)

- Model No

- Hz8-1:9

- Safety Systems

- Emergency stop, overload relay

- Number of Channels

- Up to 9 channels

- Max. Gluing Width

- 420 mm

- Spare Parts Availability

- Readily available

- Gluing Pattern Control

- Programmable, digital selection

About Cold Gluing Systems Machine Hz8-1:9 Multi Channel

Technical parameters:

Model :Taping & Gluing Machine JYD-1100TC

Electricity :AC220V 50~60Hz

Total Power:2.3KW

Max Running speed: 50 m/min

G.Weight: 1050Kg

Max Product size: 1100*1500mm

Min Product size: 120*100mm

Machine size: 4.2*1.5*1.5m

Wooden package box size 3.55*1.65*1.8m

Versatile Multi Channel Gluing

The Hz8-1:9 Cold Gluing Machine supports up to 9 distinct gluing channels, allowing users to handle diverse production requirements from carton sealing to bookbinding. Its programmable controls enable rapid adaptation to different job specifications, making it an ideal choice for various industrial applications requiring precise, multi-point glue application.

User-Friendly Interface and Controls

Featuring an intuitive touch screen (HMI), operators can effortlessly manage settings and monitor the machine. The microcontroller/PLC-based control system ensures accuracy in glue application, while Ethernet and USB connectivity options provide easy software updates and system integrations.

Robust Safety and Reliability

Safety features like emergency stop and overload relay prioritize operator protection. The sturdy, powder-coated heavy-duty steel frame ensures stability, while the air-cooled and automatic lubrication systems maintain optimal performance and longevity even during demanding productions.

FAQs of Cold Gluing Systems Machine Hz8-1:9 Multi Channel:

Q: How does the Hz8-1:9 Cold Gluing System enhance production efficiency?

A: With up to 9 independently programmable channels and a high production rate of up to 9,000 pieces per hour, the Hz8-1:9 enables simultaneous multi-line gluing. The fast changeover capabilities and digital pattern selection further reduce downtime, optimizing workflow for demanding industrial environments.Q: What types of glue and materials are compatible with this machine?

A: The Hz8-1:9 operates using water-based cold glue and can handle paper substances with a minimum thickness of 90 gsm. This makes it suitable for applications including carton sealing, packaging, bookbinding, and paper bag making, ensuring strong, consistent adhesion.Q: When is it necessary to change the glue pattern, and how is this accomplished?

A: Changing the glue pattern is required when switching between different production tasks or material types. The process is streamlined via the digital touch screen (HMI), allowing quick selection and programming of various gluing patterns without manual adjustments, enabling fast and error-free changeovers.Q: Where can the Hz8-1:9 be installed, and what are the installation requirements?

A: This machine is designed for use in industrial settings such as printing, packaging, and manufacturing plants. It requires a standard 220V/50Hz electric supply, 0.3 - 0.6 MPa air pressure, and sufficient shop floor space for its dimensions (1200 550 850 mm). Professional installation support is available upon request.Q: What maintenance is needed to ensure optimal operation of the Hz8-1:9?

A: Routine maintenance is minimal, thanks to the machines automatic lubrication and air-cooled systems. Users should periodically inspect the glue supply and system components, while spare parts are readily available to support any required replacement or repair.Q: How does the touch screen interface benefit daily operations?

A: The touch screen (HMI) offers convenient access to all programmable settings, gluing pattern configurations, and real-time operational data. This reduces operator training time, minimizes errors, and supports efficient machine management through visual prompts and status updates.Q: What are the key advantages of using the Hz8-1:9 for multi-channel gluing applications?

A: The key benefits include multi-channel capability for higher productivity, precise programmable glue application, low noise levels (<70 dB), robust safety features, quick setup, minimal maintenance, and broad compatibility with various packaging and printing tasks, making it a versatile investment for manufacturers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tape Applicator Machine Category

Cold Gluing Systems Machine Hz4-8 Channel

Price 9999 USD ($) / Set

Minimum Order Quantity : 1 Set

Power Source : Other, Electric

Operating Type : Automatic

Surface Treatment : Other, Powder Coated

Technology : Other, Advanced Nozzle Control

Cold Gluing Systems Machine Hz4-4Channel

Price 99999 USD ($) / Set

Minimum Order Quantity : 1 Set

Power Source : Other, Electric plugin

Operating Type : Other, Automated

Surface Treatment : Other, Smooth exterior finish

Technology : Other, Cold gluing technology

Large Spool Holder Adhesive Tape Applicator

Price 5555 USD ($) / Set

Minimum Order Quantity : 1 Set

Power Source : Other, Manual

Operating Type : Other, Handoperated

Surface Treatment : Other, Powder Coated

Technology : Other, Mechanical

Cold Gluing Systems Machine Hz4-br4 Flexo Print

Price 9999 USD ($) / Set

Minimum Order Quantity : 1 Set

Power Source : Electricity

Operating Type : Semi Automatic

Surface Treatment : Painted

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry