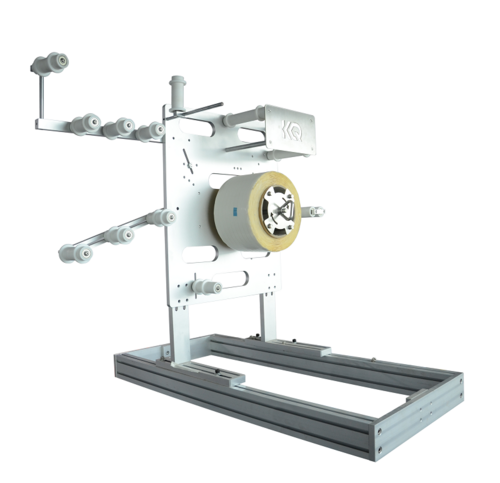

Cold Gluing Systems Machine Hz4-8 Channel

Price 9999 USD ($)/ Set

Cold Gluing Systems Machine Hz4-8 Channel Specification

- Noise Level

- 65 dB (A)

- Control System

- Microprocessor Based

- Connectivity Options

- RS232/RS485 ports

- Power Rating

- 600W

- Accuracy

- 0.5 mm

- Frame Type

- Robust Metal Frame

- Motor Power

- 0.25 kW

- Voltage

- 220V / 50Hz

- Operating Temperature

- 5C - 40C

- Frequency

- 50 Hz

- Cooling System

- Air Cooling

- Lubricating System

- Automatic Lubrication

- Production Capacity

- Up to 20,000 pieces/hour

- Drive

- Electric Motor Drive

- Features

- Precise Glue Application, Programmable Controls, Multi-Channel Operation

- Machine Type

- Cold Gluing Machine

- Model No

- HZ4-8

- Product Type

- Cold Gluing System

- Technology

- Advanced Nozzle Control

- Power Source

- Electric

- Operating Type

- Automatic

- Power

- 600 W

- Pressure

- 0.2 - 0.8 MPa

- Surface Treatment

- Powder Coated

- Dimension (L*W*H)

- 780 x 380 x 320 mm

- Weight (kg)

- 39 kg

- Color

- Blue and White

- Usage & Applications

- Packaging, Bookbinding, Folding Cartons, Corrugated Products

- Mounting Options

- Tabletop/Inline Mounting

- Nozzle Type

- High-precision Solenoid Valve

- Service Support

- On-site Installation & Training Available

- Max. Viscosity Tolerance

- 2000 mPa.s

- Built-In Memory

- Program up to 100 job settings

- Energy Consumption

- Low Power Consumption Design

- Glue Type

- Water-based cold glue

- Input Signal

- Photoelectric or Mechanical Switch

- Gluing Pattern Control

- Customizable Dot/Line Patterns

- Safety Features

- Emergency Stop, Overload Protection, Short Circuit Protection

- Number of Channels

- 4-8 independent channels

- Compliance

- CE Certified

- Ambient Humidity

- 10%-80% RH (non-condensing)

- Display Interface

- Digital Human-Machine Interface (HMI)

- Response Time

- 3 ms

Cold Gluing Systems Machine Hz4-8 Channel Trade Information

- Minimum Order Quantity

- 1 Set

- Payment Terms

- Cash Advance (CA)

- Main Domestic Market

- All India

About Cold Gluing Systems Machine Hz4-8 Channel

High precision components are equipped with high frequency solenold valve to ensure nondestructive gluing when working at high speed.

8 "or 15" screen touch screen, each gun can applicated 8 sections of glue samples, and support point and line exchange. One-key switch to different types of product which in to control interface.

Various types of guns, application of different situations and glue projects, can be customization.

Advanced Multi-Channel Control

The HZ4-8 machine features 4-8 independent glue channels, customizable dot or line patterns, and a microprocessor-based control system for exceptional accuracy (0.5 mm). Operators benefit from a digital HMI interface that enables seamless setup, on-the-fly adjustments, and programming of up to 100 job settings, providing unmatched flexibility for diverse applications.

Built for Industrial Reliability

Constructed with a robust powder-coated metal frame, the HZ4-8 is designed for intensive use. Key safety features include emergency stop, overload, and short circuit protection. Air cooling and automated lubrication systems maintain peak performance while ensuring quiet operation ( 65 dB(A))-making it ideal for busy production environments.

Versatile Applications and Connectivity

Perfect for packaging, bookbinding, folding cartons, and corrugated products, the HZ4-8 supports both tabletop and inline mounting. With RS232/RS485 connectivity, it integrates easily into modern production lines. The machine's 780 x 380 x 320 mm compact footprint and 220V/50Hz compatibility fit a range of factory settings.

FAQ's of Cold Gluing Systems Machine Hz4-8 Channel:

Q: How does the HZ4-8 Cold Gluing System machine ensure precise glue application?

A: The HZ4-8 Cold Gluing System employs high-precision solenoid valve nozzles and a microprocessor-based control system, providing glue placement accuracy within 0.5 mm. The built-in digital HMI allows precise pattern programming and enables operators to customize dot or line gluing to suit specific project requirements.Q: What types of jobs and industries can benefit from using this gluing machine?

A: This machine is ideal for high-throughput applications such as packaging, bookbinding, folding carton assembly, and corrugated product manufacturing. Its capability to run up to 20,000 pieces per hour makes it a reliable asset in environments demanding fast, consistent, and controlled adhesive application.Q: When is it recommended to use the programmable controls and memory function?

A: Programmable controls and built-in memory (up to 100 job settings) are best utilized for operations that require frequent batch changes or diverse gluing patterns. This feature streamlines setup and reduces downtime, as operators can quickly switch between preprogrammed job configurations as production demands.Q: Where can the HZ4-8 machine be installed, and does it offer flexibility in mounting?

A: The HZ4-8 supports both tabletop and inline mounting, offering flexibility for varied production setups. Its compact design and robust construction make it suitable for integration into new or existing manufacturing lines in factories or workshops.Q: What benefits does the advanced nozzle control technology provide?

A: Advanced nozzle control ensures rapid ( 3 ms) and accurate glue deposit, minimizing wastage and enhancing bonding quality. This results in reduced production costs, increased product reliability, and improved end-user satisfaction.Q: How does the system handle safety and maintenance?

A: The machine integrates multiple safety features including an emergency stop function, overload protection, and short circuit protection. It is equipped with an automatic lubrication system and air cooling, simplifying maintenance and ensuring consistent, trouble-free operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tape Applicator Machine Category

Automatic Thin Paper Double Side Tape Applicator Machine

Price 9999 USD ($) / Set

Minimum Order Quantity : 1 Set

Operating Type : Automatic

Power Source : Other, Electric

Surface Treatment : Other, Powder Coated

Technology : Other, Fully Automatic

Hot Melt Gluing Systems Machine

Price 5400 USD ($) / Set

Minimum Order Quantity : 1 Set

Operating Type : Semi Automatic

Power Source : Electricity

Surface Treatment : Other, Powder Coated

Technology : Other, Advanced Glue Melting Technology

Large Spool Holder Adhesive Tape Applicator

Price 5555 USD ($) / Set

Minimum Order Quantity : 1 Set

Operating Type : Other, Handoperated

Power Source : Other, Manual

Surface Treatment : Other, Powder Coated

Technology : Other, Mechanical

Cold Gluing Systems Machine Hz4-br4 Flexo Print

Price 9999 USD ($) / Set

Minimum Order Quantity : 1 Set

Operating Type : Semi Automatic

Power Source : Electricity

Surface Treatment : Painted

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry