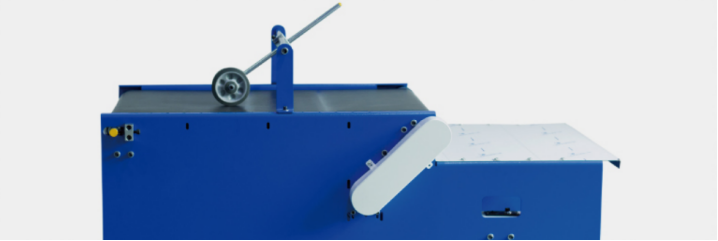

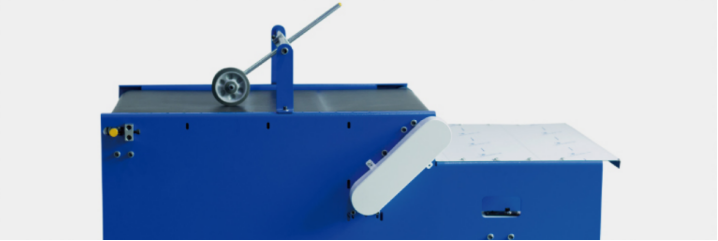

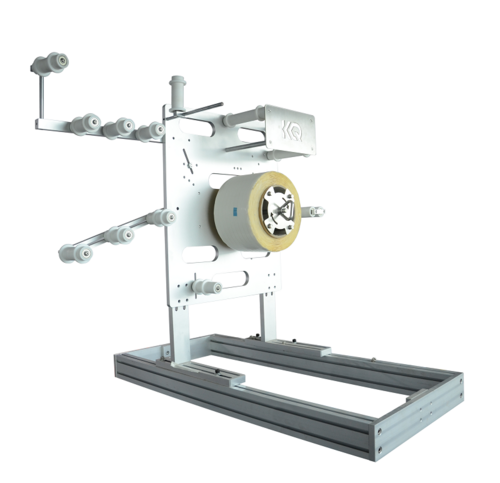

Automatic Thin Paper Double Side Tape Applicator Machine

Price 9999 USD ($)/ Set

Automatic Thin Paper Double Side Tape Applicator Machine Specification

- Accuracy

- 0.5 mm

- Plastic Processed

- None (for paper use)

- Machine Type

- Automatic Tape Applicator

- Features

- Auto tape feeding, edge sensors, waste rewinding, safety guards

- Voltage

- 220V/380V, 3 Phase

- Noise Level

- <72 dB(A)

- Frequency

- 50/60 Hz

- Drive

- Servo Motor Drive

- Lubricating System

- Centralized Lubrication

- Power Rating

- 2.2KW

- Model No

- ATDSTM-350

- Cooling System

- Air Cooling

- Motor Power

- 1.5 kW AC Motor

- Connectivity Options

- USB, Ethernet

- Frame Type

- Heavy-duty steel frame

- Control System

- PLC Controlled, Touch Screen Interface

- Production Capacity

- 3000 - 4000 pcs/hour

- Operating Temperature

- 5C to 40C

- Product Type

- Double Side Tape Applicator Machine

- Technology

- Fully Automatic

- Power Source

- Electric

- Operating Type

- Automatic

- Power

- 2.2 kW

- Pressure

- Adjustable pneumatic system, up to 0.6 MPa

- Surface Treatment

- Powder Coated

- Dimension (L*W*H)

- 1800 x 950 x 1650 mm

- Weight (kg)

- Approx. 450 kg

- Color

- Industrial Grey & Blue

- Usage & Applications

- Application of double side tape on thin paper, stationery, label and sticker industries

- Machine Material

- Mild Steel & Aluminium

- Min Paper Thickness

- 40 gsm

- Tape Core Size

- 3 inch (76 mm)

- Safety Features

- Emergency stop, safety interlocks, overload protection

- Tape Placement Tolerance

- ±0.2 mm

- Splicing Option

- Automatic/Manual Splicing

- Max Tape Length

- 100 m

- Ambient Humidity

- 10% - 90% RH (non-condensing)

- Max Roll Diameter

- 400 mm

- Tape Width Range

- 5 mm to 25 mm

- Operator Interface

- 7-inch HMI Touch Panel

Automatic Thin Paper Double Side Tape Applicator Machine Trade Information

- Minimum Order Quantity

- 1 Set

- Main Domestic Market

- All India

About Automatic Thin Paper Double Side Tape Applicator Machine

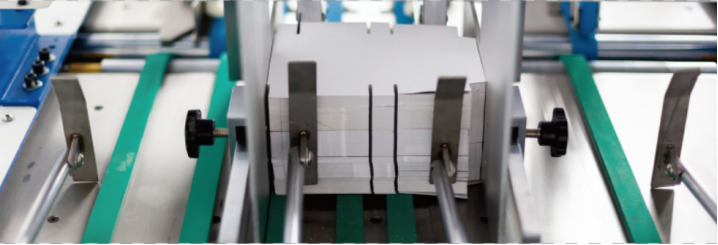

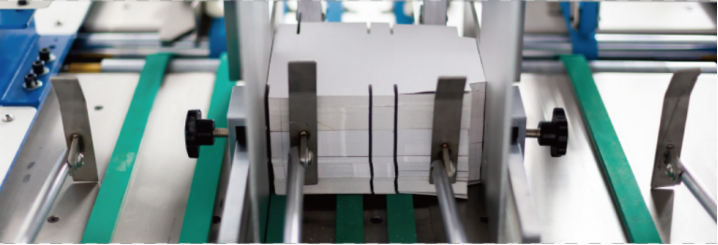

Automatic Double-Sided Tape Applicators use the new technology and design. This machine is developed special for high-end cardboard, color boxes and cartons. Automatic feeding and calibration section make this machine more efficient and more precise. It applies to tag, label, envelope, online shopping box, package of IT products, paper bags etc. Except the efficient and precise features, it can freely set up the double side tape length and sections you want to cut. Nearly, the sales of this machine have huge leaps at domestic and aboard. With the good quality and highly appreciated from customers, the machine is long term sale out Europe and America. This machine is the most ideal equipment for double side tape sticking.Superior Precision for Thin Paper Taping

Achieve precise tape application on ultra-thin paper with the ATDSTM-350, offering tape positioning accuracy of up to 0.2 mm. Edge sensors, servo drive, and PLC control ensure consistent results, meeting the demands of quality-sensitive industries such as label and stationery production. The adaptable tape width and automatic splicing streamline operational efficiency.

Robust Construction and User-Friendly Interface

Crafted from durable mild steel and aluminium, the ATDSTM-350 is engineered for long-term industrial use. The intuitive 7-inch HMI touch panel allows operators to quickly adjust settings, monitor production parameters, and respond to error alerts. Safety is paramount, with emergency stops, interlocks, and overload protection built in.

High Output and Versatile Applications

With a production capacity of 3,000-4,000 pieces per hour, this machine handles various tape functions across paper types from 40 gsm upwards. It is widely applied in the paper, stationery, sticker, and label industries for reliable high-speed tape application, making it a valued asset for manufacturers, exporters, and suppliers worldwide.

FAQ's of Automatic Thin Paper Double Side Tape Applicator Machine:

Q: How does the ATDSTM-350 ensure accurate tape placement on thin paper?

A: The ATDSTM-350 utilizes a servo motor drive, advanced edge sensors, and PLC-controlled logic to position tape with a tolerance of 0.2 mm, ensuring consistent accuracy across sheets as thin as 40 gsm.Q: What is the typical process for using this automatic tape applicator machine?

A: Operators load the paper and tape roll, configure settings via the 7-inch HMI touch panel, adjust pneumatic pressure as needed, and select either automatic or manual splicing. The system then feeds and applies tape precisely, with cut ends and tape waste rewound automatically.Q: When is automatic splicing recommended during operation?

A: Automatic splicing is recommended for uninterrupted, high-volume production runs. It seamlessly joins new tape rolls to minimize downtime and enhance operational efficiency, while manual splicing offers control during setup or specific production scenarios.Q: Where can this machine be integrated within industrial operations?

A: This tape applicator is suitable for facility lines in stationery, label, and sticker production environments, including manufacturing, converting, and packaging sectors that require reliable tape application on thin paper substrates.Q: What safety features are included in the ATDSTM-350 and how do they work?

A: The machine incorporates emergency stop buttons, safety interlocks on access panels, and overload protection systems. These features immediately halt the machine to prevent accidents, safeguarding both operator and equipment.Q: How does the ATDSTM-350 benefit paper product manufacturers and suppliers?

A: Manufacturers and suppliers benefit from increased productivity thanks to high-speed, fully automatic operation, precision tape placement, reduced waste, and features that enable integration and monitoring through modern connectivity options.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tape Applicator Machine Category

Hot Melt Gluing Systems Machine

Price 5400 USD ($) / Set

Minimum Order Quantity : 1 Set

Operating Type : Semi Automatic

Power Source : Electricity

Surface Treatment : Other, Powder Coated

Technology : Other, Advanced Glue Melting Technology

Cold Gluing Systems Machine Hz4-4Channel

Price 99999 USD ($) / Set

Minimum Order Quantity : 1 Set

Operating Type : Other, Automated

Power Source : Other, Electric plugin

Surface Treatment : Other, Smooth exterior finish

Technology : Other, Cold gluing technology

Large Spool Holder Adhesive Tape Applicator

Price 5555 USD ($) / Set

Minimum Order Quantity : 1 Set

Operating Type : Other, Handoperated

Power Source : Other, Manual

Surface Treatment : Other, Powder Coated

Technology : Other, Mechanical

Cold Gluing Systems Machine Hz4-br4 Flexo Print

Price 9999 USD ($) / Set

Minimum Order Quantity : 1 Set

Operating Type : Semi Automatic

Power Source : Electricity

Surface Treatment : Painted

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free