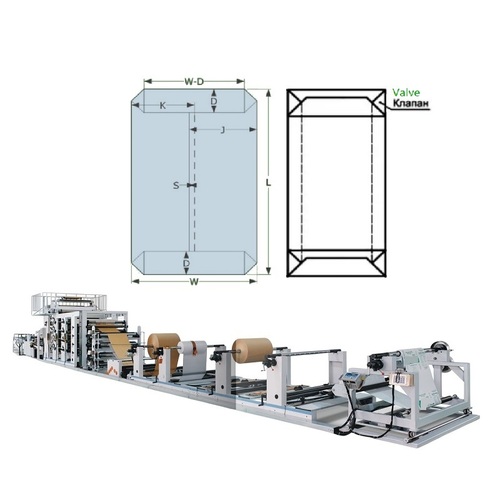

Tuber Machine 3 Layer Paper and 1 Film Industrial Valve Bag feed bag Kraft Paper Cement Bag Product Line

Price 585000 USD ($)/ Set

Tuber Machine 3 Layer Paper and 1 Film Industrial Valve Bag feed bag Kraft Paper Cement Bag Product Line Specification

- Product Type

- Tuber Machine 3 Layer Paper & 1 Film Valve Bag Production Line

- General Use

- Industrial packaging and bag forming for cement, chemicals, feed, and kraft paper bags

- Efficiency

- High-speed bag formation, up to 120 bags per minute

- Weight (kg)

- 5800 kg

- Automatic Grade

- Automatic

- Drive Type

- Servo Motor Driven

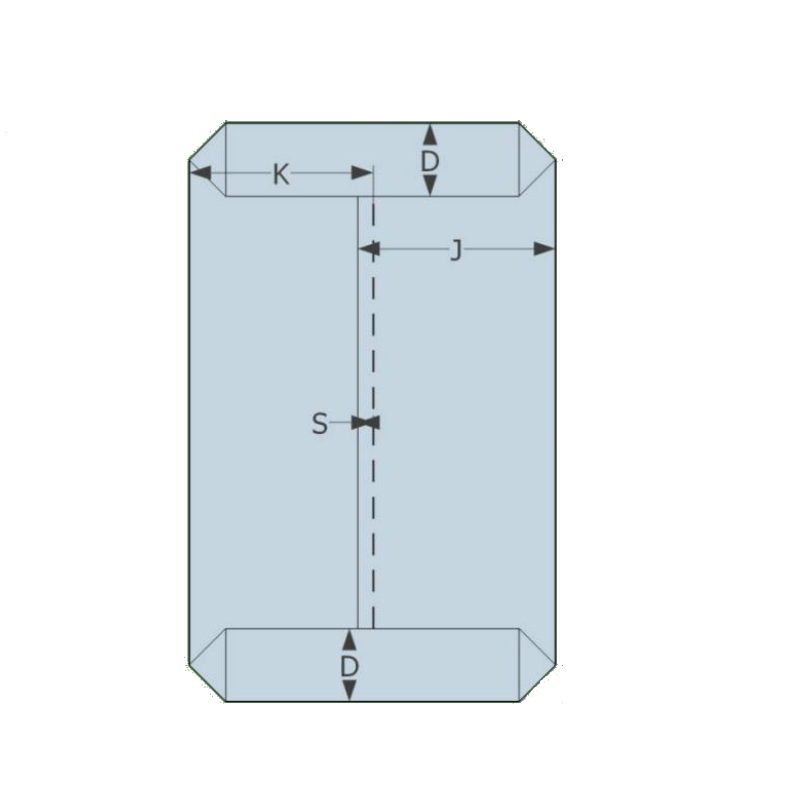

- Bag Type

- Valve Sack/Valve Bag

- Computerized

- Yes

- Photoelectric Correction

- Included

- Film Length Counter

- Digital Length Counter

- Bag Length

- Adjustable, typically 350mm - 900mm

- Power

- 25 kW

- Voltage

- 380V/50Hz (customizable)

- Material

- 3 Layer Kraft Paper + 1 Polyethylene Film

- Dimension (L*W*H)

- 9800mm x 2100mm x 2000mm

- Feature

- Multi-layer structure, high sealing strength, dust-proof, leak-proof

- Color

- Industrial Standard (Customizable)

- Production Speed

- Maximum 7200 bags/hour

- Operator Requirement

- 2-3 persons

- Sealing Type

- Ultrasonic & Hot Sealing

- Film Thickness Range

- 30 ~ 80 microns

- Noise Level

- Less than 75 dB

- Paper GSM Range

- 70 ~ 120 GSM

- Machine Structure

- Heavy Duty Welded Frame

- Raw Material Width

- 900 mm maximum

- Control System

- PLC Touch Screen

- Installed Capacity

- 28 kW

- Core Mechanism

- Automatic Paper Web Alignment

- Max Bag Width

- 700 mm

- Safety Features

- Emergency Stop, Overload Protection

- Bag Application

- Cement, Chemicals, Feed, Building Materials

About Tuber Machine 3 Layer Paper and 1 Film Industrial Valve Bag feed bag Kraft Paper Cement Bag Product Line

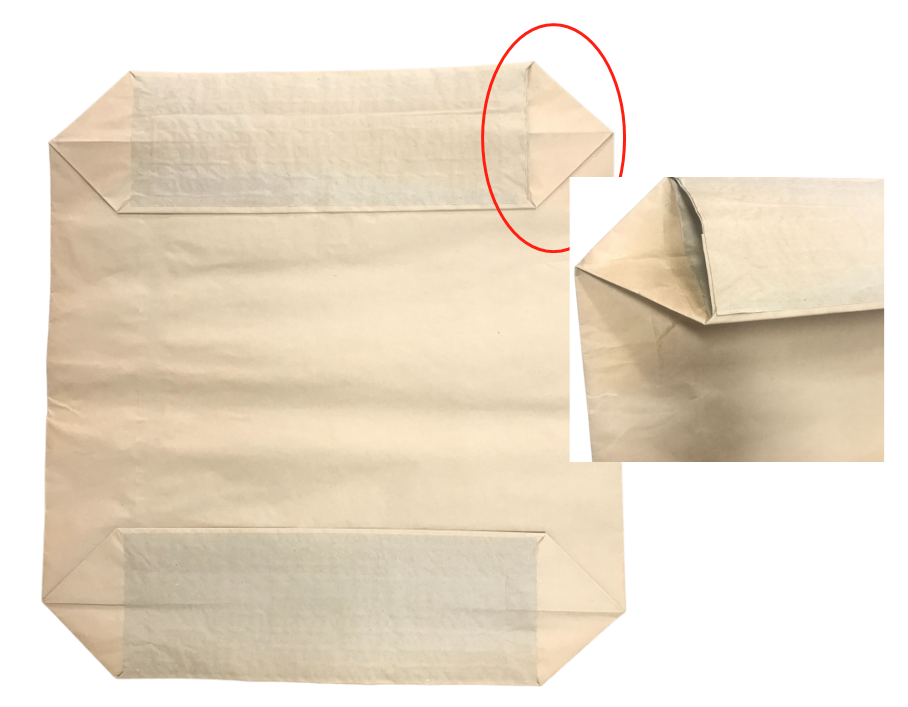

Tuber machine Cement paper bag machine

This machine is a professional kraft paper bag making machine for cement bag,

chemical bag Sack bag making.

It can make 2-4 papers+ 1 PE, 5layers bags.

The whole machine consists of Tuber Machine and Bottomer machine .

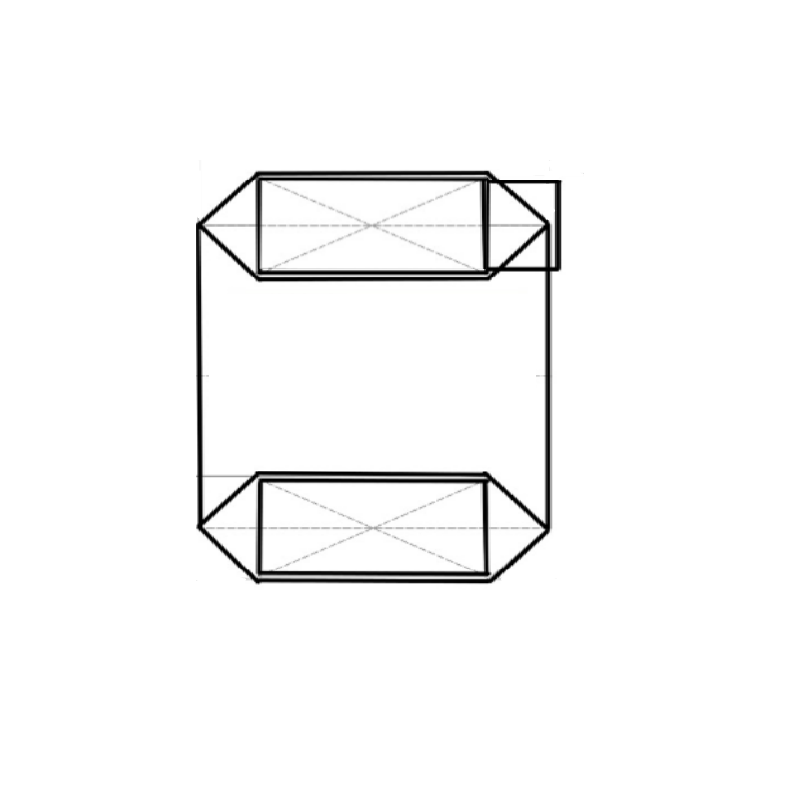

Tuber Machine

Standard configuration is Flake valve ,Stepped cutting,and with 4 color printing

Bottomer Machine

Bottomer Standard configuration

Bag Length: 370-770mm

Bag Width:350-550mm

Bottom Width:90-150mm

bag Center Distance: 280-620mm

Flake Valve Length: 120-250mm

External Reinforcement Length:260-380mm

Vacuum pump suction rate 250m3/h

Vacuum Pump Vacuum Degree -80kPa

Speed bags/min: 120150pcs/min

Option:

External Reinforcement,

2 color printing for External Reinforcement.

Flake valve for cement bag,

Out valve for Sack bag and chemical bag

High-Speed & Automated Efficiency

Engineered with a servo motor-driven system, the Tuber Machine achieves production speeds up to 7,200 bags per hour-equivalent to 120 bags per minute. It requires only 2-3 operators due to its full automation, automatic web alignment, and computerized controls, making it ideal for high-volume industrial packaging lines and maximizing throughput while reducing labor costs.

Robust Build for Industrial Demands

This machine is constructed with a heavy-duty welded frame, ensuring durability even under sustained use. Its advanced sealing options, including ultrasonic and hot sealing, guarantee high-strength, leak-proof, and dust-proof industrial bags. The structure supports raw material widths up to 900 mm and accommodates bag sizes tailored for diverse applications, from cement to chemicals and animal feed.

Versatile Packaging Applications

Designed for industrial applications, the Tuber Machine produces valve bags suitable for cement, chemicals, feed, and building material packaging. The multi-layer structure-three layers of kraft paper with one polyethylene film-provides excellent protection against dust and leaks, ensuring safe storage and transportation of material. The system offers adjustability in bag length and thickness to meet a range of industrial needs.

FAQ's of Tuber Machine 3 Layer Paper and 1 Film Industrial Valve Bag feed bag Kraft Paper Cement Bag Product Line:

Q: How does the Tuber Machine ensure precise bag formation and quality?

A: The Tuber Machine uses a combination of servo motor drive, automatic paper web alignment, and PLC touch screen controls to deliver precise, consistent bag formation. Photoelectric correction, digital length counters, and computerized settings ensure each bag meets strict quality standards for size, sealing, and strength.Q: What materials can the machine process, and what bag types does it produce?

A: It processes 3-layer kraft paper and one layer of polyethylene film, accommodating GSM ranges between 70 and 120 and film thicknesses of 30-80 microns. The machine specializes in making multi-layer valve sacks and valve bags tailored for cement, chemicals, feed, and building material packaging.Q: When is it suitable to use this machine for your packaging needs?

A: This machine is best used when you require high-volume, dust-proof, and leak-proof packaging for industrial applications such as cement, chemicals, and animal feed. Its high-speed and automatic operation make it ideal for large-scale production demands.Q: Where can the Tuber Machine be installed, and what space is required?

A: The Tuber Machine is suitable for industrial production floors or large packaging facilities. Its dimensions are 9800mm in length, 2100mm in width, and 2000mm in height, so a sufficiently spacious and well-ventilated area with 380V/50Hz electrical supply is needed.Q: What is the operational process for bag manufacturing with this equipment?

A: Raw material rolls (kraft paper and film) are loaded, automatically aligned, and processed through the machine. The servo-driven mechanism cuts, aligns, and seals the layers using ultrasonic and hot sealing methods. Finally, bags are formed, counted, and stacked, all controlled through the PLC touch screen interface.Q: How does the machine benefit your industrial packaging operations?

A: With high productivity (up to 7200 bags/hour), outstanding sealing quality, reduced labor requirements, and versatility in bag size and material, this machine increases packaging reliability, efficiency, and safety. Features like emergency stop and overload protection further ensure safe, continuous operation.Q: What maintenance and safety precautions are included?

A: The Tuber Machine comes with an emergency stop button, overload protection, and noise levels below 75 dB. Routine maintenance mainly involves regular checks on sealing mechanisms, alignment systems, and lubrication; the PLC system signals alerts for necessary interventions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cement Bag Machine Category

High Speed Bottomer Sack Bag Cement Paper Bag Making Machine

Price 585000 USD ($) / Set

Minimum Order Quantity : 1 Set

Drive Type : Other, Mechanical/Electric

General Use : Cement Bag Production

Computerized : Yes

Automatic Grade : Automatic

Paper Cement Bag Sack Bag Making Machine Product Line Kraft Paper Sack Bag Cement Paper Bag Machines

Price 600000 USD ($) / Set

Minimum Order Quantity : 1 Set

Drive Type : Mechanical, Other

General Use : Manufacturing paper cement bags

Computerized : Yes

Automatic Grade : Automatic

Paper Bag Making Machine

Price 655000 USD ($) / Set

Minimum Order Quantity : 1 Set

Drive Type : Other, Servo Motor

General Use : Paper Bag Manufacturing

Computerized : Yes

Automatic Grade : Automatic

Kraft Paper Cement Bag Machine

Price 655000 USD ($) / Unit

Minimum Order Quantity : 1 Container

Drive Type : Electric

General Use : Bag making machine

Computerized : Yes

Automatic Grade : Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free